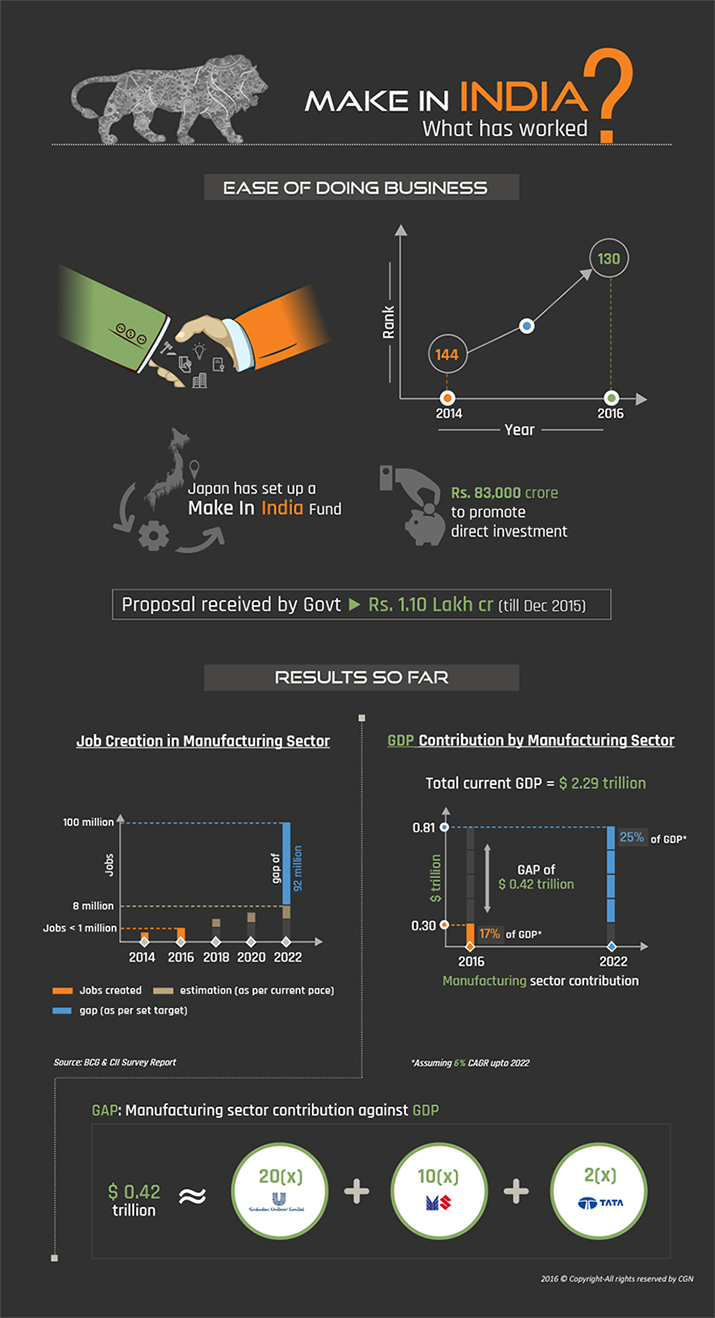

How have ‘Make in India’ initiative performed until now? Are we on the right track to achieve the set targets? ‘Make in India’ initiative launched in Sep 2014 with twin objectives, one is to generate 100 million jobs by 2022 and the other is to increase manufacturing sector contribution to overall GDP. The government took a series of steps to increase the skill level, lure the foreign investors, ease of doing business and, much more. Are these steps sufficient or more is required?

On the positive side

Many industries such as mobile manufacturers to carmakers have shown overwhelming interest. The government received proposals worth INR 1.10 lakh crore up to Dec last year. In addition to this, many countries such as Japan and the US particularly are actively supporting this initiative. Japan has set up a ‘Make in India’ fund of about INR 83,000 crore to promote direct investment and support the Japanese companies in India regarding their business activities.

Data does not lie

On the contrary, as per a CII survey, India has not created sufficient manufacturing jobs in the last couple of years. With the current pace, India will only be able to generate 8 million jobs by 2022. Moreover, the proportion of manufacturing to GDP has been stuck at around 17 percent from the last five years, below the government’s goal to ramp it up to 25 percent.

Apart from this, FDI inflow figures of last two years suggest that investments in service and software sector have grown higher vis-à-vis the manufacturing sector. In the multiple rounds, the government has eased up and opened gates of FDI in many sectors including defense and railways. Although, there is a skepticism about the speed of policy changes. Whenever one over-communicate and under-deliver, the biggest risk is that they begin to lose trust.

Emphasize on

To increase the pace of development and to gain the confidence of investors, the key focus should be on the infrastructure development, quality and enhancing the skills for its exports to compete internationally.

- The government has rightly started the ‘Skilled India’ mission last year, though it has not picked up the required speed of implementation. As per the CII’s India skill report, 34 percent people were found employable out of about 100,000 candidates. Therefore, one can imagine the condition of the talent pool and a kind of effort required to put them to train.

- The quality is a major concern in the past including last two years. Around 700,000 cars recalled in last five months is a testimony to this fact. To compete at the international level, zero defect policy must be adopted.

- Greater efforts are required to upgrade skills of people at the shop floor to enhance quality standards. Employing higher skilled labor in the manufacturing sector would make India produce higher quality goods at a much lesser cost.

To sum up, I would say the government has acted reasonably well in the last couple of years. They have shown a positive intent and taken aggressive steps in the right direction to make it successful. Lawmakers should realize that it is a marathon rather than a sprint. To get a change in an organization is tough, so one can imagine the efforts required for the changes in entire country. This cannot be done overnight, however, razor sharp focus is further required on the basic infrastructure, putting the processes in place, skill development and, quality standards.

REFERENCES:

http://www.livemint.com/Companies/ENDu7ngdUSL0yd60xtC8yM/Maruti-Suzuki-cracks-down-on-suppliers-over-quality.html

http://www.business-standard.com/article/economy-policy/govt-unlikely-to-meet-make-in-india-targets-on-jobs-manufacturingsurvey- 115092700218_1.html

http://www.makeinindia.com/home

Something we found interesting

25eb.png?width=203&name=CGN_Tagline1%20(1).png)