NVIDIA, a leading electronic component supplier (chipmaker), faced a big challenge in forecasting customer demand & positioning its inventory levels accurately to meet that demand.

Information required to create inventory reports was housed in various systems, so the production department used spreadsheets to build rough inventory forecasts. In 2005, the overall forecast accuracy was 95% (forecast error ~ 5%). This meant that when the company had $500 million in inventory, the forecast error led to a mismatch of inventory of up to $25 million.

A deep dive revealed the need to adopt technology to forecast better through detailed inputs. In order to capture & consolidate wider array of inputs, the firm moved to implementation of new IT enterprise demand planning system. These systems managed to capture inputs from different divisions & then consolidated to come up with the overall forecast numbers.

"The forecast accuracy of NVIDIA was increased to 98% by implementationof IT enterprise demand planning system in 2 quarters"

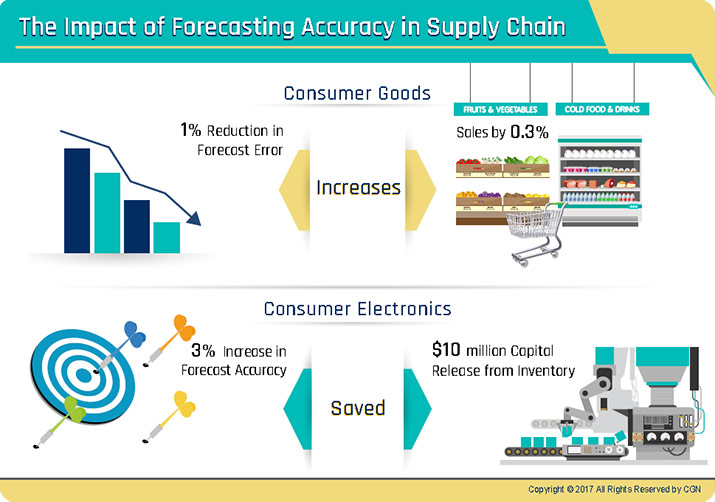

This small change in forecast error (net change of 2%; forecast error was reduced from 5% to 3%), resulted into the capital release of nearly $10 million.

Forecasting is vital to businesses in order to streamline their supply chains though it inherently comes with an error component. Many companies find forecasting challenging but they prioritize it to improve cost effectiveness and product availability in the supply chain.

"A company like Reliance Industries (annual turnover $44 Billion) can save $130 Million every year by improving forecast accuracy"Typical Challenges in Forecasting

- New product introductions: Key difficulty lies in the ability to forecast customer trends for new products with no historical data as reference. Judgement of which products are going to sell very well and adequately available to meet the demand, is always tricky

- Fluctuations of sales volumes: The variations in sales volumes can lead to excess inventory or stock-outs across the supply chain

- Lack of good stock visibility (of all SKUs and stock levels)

How to improve forecast accuracy

Perfect information & accurate forecasting exists only in an ideal world. It is rightly by Paul Saffo, “The goal of forecasting is not to predict the future but to tell you what you need to know to take meaningful action in the present”.

In the current commercial global village, information flow gaps & rapidly changing customer trends lead to less than accurate forecasting. The forecasting accuracy can be improved by cloud based softwares.

"Cloud based demand planning softwares are contributing to significant improvement in forecasting techniques & yielding benefits such as reducing capital costs & improving sales revenue."CGN Global, has vast experience in delivering data analytics & inventory optimization projects for large global clients across automotive, retail & healthcare sectors.

References

https://ibf.org/index.cfm?fuseaction=showObjects&objectTypeID=87

http://www.supplychaindigital.com/top-10/seven-reasons-why-you-need-forecast-supply-chain

http://muddassirism.com/2016/06/importance-of-demand-forecasting-in-supply-chain/

https://scm.ncsu.edu/scm-articles/article/forecasting-methods

http://sapinsider.wispubs.com/Assets/Case-Studies/2012/April/NVIDIA-Saves-Millions-Through-Improved-Forecasting-Accuracy

What we found interesting

"Here is an interesting blog on effect offorecast accuracy in supply chains:"

https://www.logility.com/blog/hank-canitz/march-2017/simplify-supply-chain-forecasting

25eb.png?width=203&name=CGN_Tagline1%20(1).png)